How to solve the Fault of special parts of Powder filling machine by yourself?

Powder filling machine is mainly used for quantitative packaging of powder materials, and is suitable for quantitative packaging of powder, powder and powder materials in chemical, pharmaceutical, food, agricultural and sideline products and other industries.

The industry pointed out that nowadays, the use of powder filling machine in many industries can be said to be very simple, but whether it is semi-automatic or fully automatic, there will inevitably be some problems after a long time, especially for some customers who do not understand the machine, they will often be confused when they encounter faults. So, in the face of failure, how to find and solve the problem?

1st.PLC fault

Technicians pointed out that if the motor is controlled at this point, the fault phenomenon is that the motor runs after a signal is sent to start the motor, but the motor does not stop running after the stop signal is sent. The motor stops running only after the PLC is powered off; If this point controls the solenoid valve, the fault phenomenon is that the solenoid valve coil is continuously energized and the cylinder does not reset.

In view of the above situation, it is suggested to separate the adhesion points by hitting the PLC with external force to help judge the fault.

2nd.Magnetic switch failure

The magnetic switch is mainly used to detect the position of the cylinder and control the stroke of the cylinder. The actions of the four cylinders of lamination, pushing ladle, pressing ladle and melting knife are interrelated. The magnetic switch is used to detect and control their position.

The magnetic switch is mainly used to detect the position of the cylinder and control the stroke of the cylinder. The actions of the four cylinders of lamination, pushing ladle, pressing ladle and melting knife are interrelated. The magnetic switch is used to detect and control their position.

It is reported that the main performance of the fault is that the subsequent cylinder does not act. The reason is that the cylinder speed of the powder filling machine is fast, resulting in the magnetic switch can not detect the signal. For example, the speed of the pushing cylinder is too fast. After the pushing cylinder is reset, the pressing cylinder and melting knife cylinder do not act.

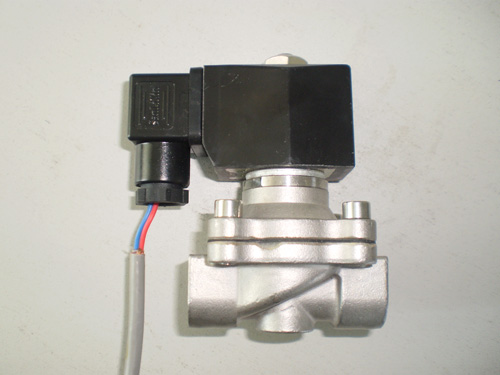

3rd.Solenoid valve failure

The failure of solenoid valve is mainly manifested in that the cylinder does not act or reset, because the solenoid valve of the cylinder cannot be reversed or blow by. In case of solenoid valve blow by, the air pressure of the machine cannot reach the working pressure and the knife beam cannot rise in place because the inlet and outlet air circuits are connected. The knife beam protection proximity switch does not work, the operating conditions of the whole machine are not established, and the machine cannot run, which is easy to be confused with electrical failure.

In view of this situation, the technicians said that they can listen to the sound source carefully and search the air leakage point by hand. Generally, it is easy to find the solenoid valve with gas channeling.