Maintenance&Precautions of filling machine

when you finished the production,there are some tips people might ignore:

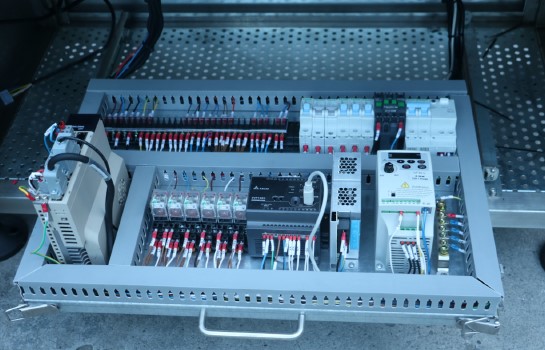

1. When the power switch is turned off, some circuits in the electrical control of liquid filling machine still have voltage. When repairing the control circuit, it is necessary to pull out the power line. If not use for a long time , remember to turn off the power supply of the electric control box, which can not only save power consumption, but also prolong the service life of the filling machine.

1. When the power switch is turned off, some circuits in the electrical control of liquid filling machine still have voltage. When repairing the control circuit, it is necessary to pull out the power line. If not use for a long time , remember to turn off the power supply of the electric control box, which can not only save power consumption, but also prolong the service life of the filling machine.

2. The second half of the liquid filling machine (close to the control button) is equipped with electrical control elements. Under no circumstances, do not flush the body directly with water, otherwise, it will be dangerous to electric shock and damage the electrical control elements.

2. The second half of the liquid filling machine (close to the control button) is equipped with electrical control elements. Under no circumstances, do not flush the body directly with water, otherwise, it will be dangerous to electric shock and damage the electrical control elements.

3. Use power and air sources that meet the requirements of liquid filling machine.

4. To prevent electric shock, the machine should be well grounded. Please provide a power socket with bottom line for liquid filling machine.

4. To prevent electric shock, the machine should be well grounded. Please provide a power socket with bottom line for liquid filling machine.

5. for parts in contact with materials, it is necessary to clean them in time to avoid loss caused by product pollution