Description

UVGG-12series high-speed filling machine adopts linear tracking filling and multi head capping mode. The whole process is continuously balanced and the quality is improved. The equipment is composed of bottle arranging conveyor belt, positioning mechanism, filling system, outer cover finishing and conveying mechanism, upper cover mechanism, outer cover rotating mechanism, bottle discharging system, rack, RABS (restricted access isolation system) and control part. Through the turntable and bottle feeding, the plastic bottle body is positioned by equal plates in turn. The cam drives the needle to move up and down to fill, the outer cover is arranged and transported, the cover is automatically covered, the outer cover is tracked and rotated, and finally the bottle is discharged. It can be produced by single machine or combined transportation line. It can meet the requirement of syrup irrigation According to the requirements of filling, filling accuracy and foreign matter visible in filling.

Features:

It is suitable for filling and capping 30-200ml syrup bottle.

According to the user's requirements, plunger pump, stainless steel piston pump and ceramic pump can be configured to carry out the filling, with high filling accuracy, and the filling volume can be adjusted without stopping the machine. With equal disc, the positioning is accurate and the transmission is stable. The cam drives the needle to track the filling, and multiple needles complete the filling action at one time. The filling system and the outer cover vibration plate can be disassembled, convenient for cleaning and disinfection, and easy for assembly. It adopts automatic cover hanging and tracking capping, with high qualified rate and strong adaptability. Using mechatronics technology, touch screen control panel, simple operation, variable frequency speed control. The control can achieve no bottle filling, no bottle capping.

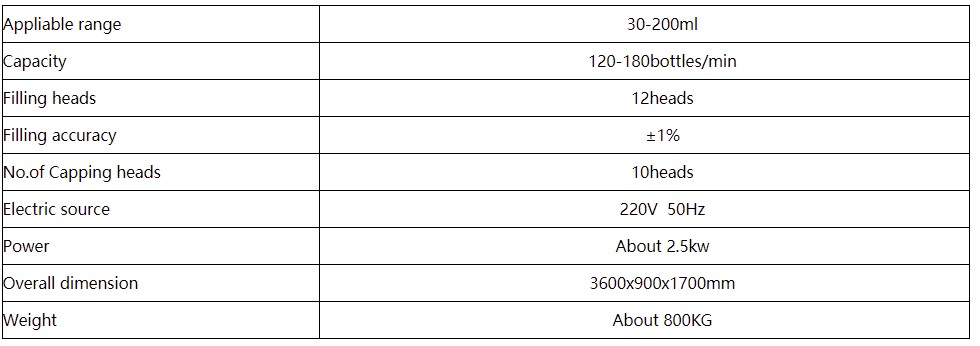

Specification

NOTE: ALL THE

SPECIFICATION ABOVE COULD BE ADJUSTED ACCORDING TO CLIENT'S DIFFERENT ACTUAL

DEMAND,WELCOME TO CONTACT US IF YOU HAVE REQUIREMENTS