Description

High speed eye drops filling machine is suitable for 2-30ml liquid filling and sealing in pharmaceutical industry. After sterilization, the bottles are arranged After filling, the plastic bottle enters the storage tank through the bottle sorting machine, synchronous wheel spacing, module transmission, tracking filling, pneumatic plugging, manipulator cap removal and tracking cap rotation,move to next process. The structure of the machine is reasonable. It uses 6 filling heads, 12 upper stoppers, and screw caps. High precision cam indexer can position the equal star disk without gap and accurately; ceramic pump can fill the bottle with accurate and adjustable measurement and convenient cleaning and maintenance; constant torque head can rotate the cap to protect the cap from injury; touch screen and PLC intelligent control

It can be controlled, operated simply and man-machine conversation is convenient. It has the functions of no bottle filling, no bottle plugging and no plug capping. The machine is controlled by gas and electricity, and it is easy to operate

The worktable is protected by stainless steel material, and the transmission is mechanical transmission. The transmission is accurate and stable, with the advantages of low loss, stable operation and stable capacity. The whole machine meets the GMP requirements.

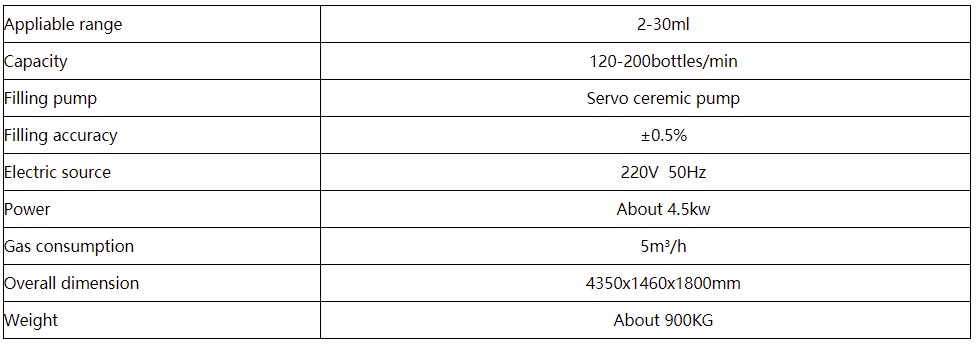

Specification

NOTE: ALL THE SPECIFICATION ABOVE COULD BE ADJUSTED ACCORDING TO CLIENT'S DIFFERENT ACTUAL DEMAND,WELCOME TO CONTACT US IF YOU HAVE REQUIREMENTS